FlexSEY

Modular Automation Cells

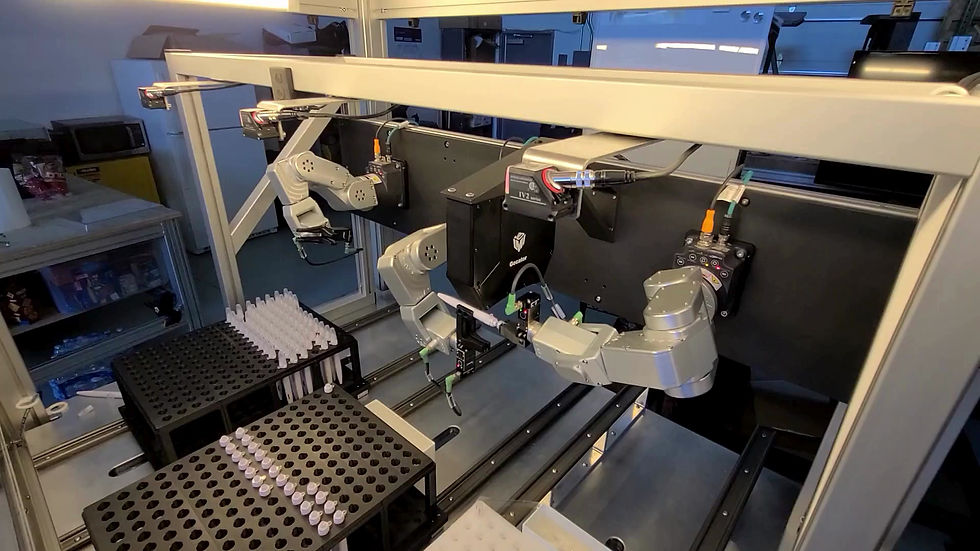

Built for adaptability, our cells enable customers to configure process-specific cell blocks for their manufacturing needs. Each cell is designed to perform distinct tasks and work in concert to enhance production flow. This approach allows for a customizable setup that aligns with the specific requirements of different products, with tooling adapted for each unique application.

%20(1)_edited.jpg)

%20(3).png)

Modular automation cells offer unparalleled customization, tailored to meet the specific demands of each application. Their flexible design allows for easy adjustments and modifications, ensuring they fit perfectly with the unique requirements of different tasks and products. This adaptability not only enhances the effectiveness of the automation process but also ensures that each module delivers maximum performance for its intended application.

Benefits of Implementing Modular Automation Cells in Industrial Automated Manufacturing

Looking for a different process? These are just a few examples - our team automates custom processes all the time. Contact us about your process!

After-Sales Support for Ongoing Productivity

We uphold the stringent reliability and performance demands of aerospace and defense processes, providing rapid-response on-site assistance across the US Southeast. Additionally, our remote support system is equipped for urgent needs, offering immediate diagnostics and resolution with our remote monitoring and troubleshooting. We guarantee expert support for your operations, maintaining the high levels of precision and efficiency essential for critical industries.

Contact Team SEYMOUR

Experience today the SAT difference – where cutting-edge technology meets unparalleled project management expertise and the speed and flexibility of in-house vertical integration, supported by a team of dedicated professionals at every stage.

_edited.png)

%20(2).png)

%20(1).png)